Edible oil refining produces the edible oil with characteristics that consumers desire such as bland flavor and odor, clear appearance, light color, stability to oxidation and suitability for frying.

Edible oil refinery plant can remove phospholipids, FFA, pigment, off-flavor and other impurities in edible oil. Edible oil refinery or vegetable oil refinery is essential to ensure the removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil, as well as to impart uniform colur by removal of coloring pigments and to get rid of unpleasant smell from the oil by removal of odiferous matter.

Edible Oil Refining Plant

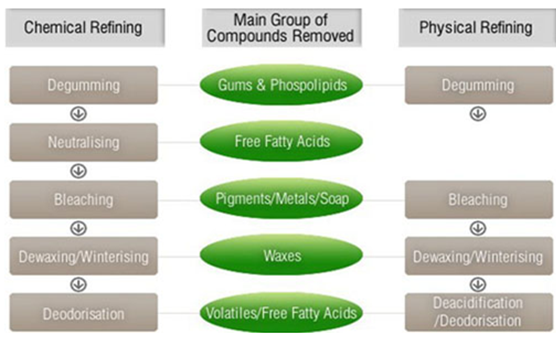

Edible oil refining comes after oil extraction, and it usually includes the following sections: Degumming, Neutralization, Bleaching, Dewaxing and Deodorization.

Degummed edible oil is heated to 65-70ºC. And the caustic soda solution is added slowly. With continuous stirring, reaction is between free fatty acid and caustic soda solution. Soap is formed. Then stirring is stop and soap will be settled down, which is removed. And 3-4 hot water wash is required to remove soap and impurities. Oil is totally neutral. Then we can use in bleaching process.

Most of all edible oils are contains gum, and it is necessary to remove them. Thus, bleaching is needed. In neutralizer, oil is heated to 60-65ºC and phosphoric acid is added 0.06-0.1% with continues stirring for ½ hour.

In deodorization, smell and fatty matter of oil are removed. Edible oil is heated to 130ºC. Then open steam is applied and oil is heated up to 180-220ºC. After constant open steam on for 3-4 hours, edible oil is cooled and then be filtered to remove impurity. Thus, the oil is ready to eat.

Edible Oil Refining Process