Flat Die Pellet Press

Our ZLSP D-Type series of flat die pellet press are specially designed for small scale pellets production. The flat did pellet press is made of a flat die, a set of rollers, feeder and gear bearings. Its driving force generally has four kinds: electrical motor, gasoline engine, diesel engine and PTO. Our flat pellet press also can be divided into two main kinds: roller rotating and die rotating. As the names of two kinds’ suggest, roller rotating flat die pellet press means the rollers are rotating while the flat die is stationary when making pellets. However, the die rotating flat die pellet press is just the opposite to roller rotating type when in operation.

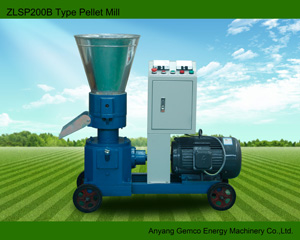

Flat Die Pellet Press with Electric Motor

|

|

| ZLSP200B Flat Die Pellet Mill | ZLSP 200C Small Flat Die Pellet Mill |

Technical Parameters

| Model | Capacity | Power | Net Weight | Outside Dimension(mm) |

|---|---|---|---|---|

| ZLSP-150B | 50-100kg/h | 3phase5.5kw | 95kg | 800*450*700 |

| ZLSP-200B | 80-120kg/h | 3phase7.5kw | 200kg | 1000*480*930 |

| ZLSP-230B | 120-200kg/h | 3phase11kw | 290kg | 1180*540*1000 |

| ZLSP-260B | 160-250kg/h | 3phase15kw | 320kg | 1240*540*950 |

| ZLSP-300B | 250-400kg/h | 3phase22kw | 350kg | 1300*560*1100 |

| ZLSP-150C | 60-110kg/h | 3phase5.5kw | 105kg | 1000*480*780 |

| ZLSP-200C | 80-120kg/h | 3phase7.5kw | 210kg | 1050*550*830 |

| ZLSP-230C | 120-200kg/h | 3phase11kw | 290kg | 1200*560*950 |

| ZLSP-260C | 160-250kg/h | 3phase15kw | 340kg | 1240*580*1000 |

| ZLSP-300C | 250-400kg/h | 3phase22kw | 425kg | 1300*620*1100 |

Flat Die Pellet Press with Electric Motor

Technical Parameters

| Model | Capacity | Power | Net Weight | Outside Dimension(mm) |

|---|---|---|---|---|

| ZLSP-150A | 50-100kg/h | 8Hp | 180kg | 1000*500*750 |

| ZLSP-200A | 80-120kg/h | 15Hp | 210kg | 1460*750*900 |

| ZLSP-230A | 120-200kg/h | 22Hp | 280kg | 1560*850*1000 |

| ZLSP-260A | 160-250kg/h | 30Hp | 330kg | 1200*500*1070 |

| ZLSP-300A | 250-400kg/h | 55Hp | 410kg | 1220*600*1000 |

Flat Die Pellet Press with Gasoline Engine

|

|

| 120Q Gasoline Flat Die Pellet Mill | 150Q Gasoline Flat Die Pellet Mill |

Technical Parameters:

| Model | Capacity | Power | Net Weight | Outside Dimension(mm) |

|---|---|---|---|---|

| ZLSP-120Q | 40-80kg/h | 7.5Hp | 120kg | 900*500*730 |

| ZLSP-150Q | 50-100kg/h | 10Hp | 180kg | 1000*500*750 |

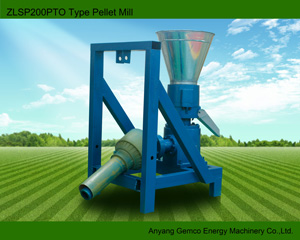

PTO Flat Die Pellet Press

Technical Parameters

| Model | Capacity | Power | Net Weight | Outside Dimension(mm) |

|---|---|---|---|---|

| ZLSP-150P | 50-100kg/h | ≥8Hp | 90kg | 900*540*1020 |

| ZLSP-200P | 80-120kg/h | ≥15Hp | 130kg | 1000*540*1020 |

| ZLSP-230P | 120-200kg/h | ≥22Hp | 175kg | 1000*540*1020 |

| ZLSP-260P | 160-250kg/h | ≥30Hp | 235kg | 1050*540*900 |

| ZLSP-300P | 250-400kg/h | ≥55Hp | 305kg | 1100*540*1000 |

Key Components of Flat Die Pellet Press

Rollers: As rollers are easily wearable, the rollers in our flat die pellet press are made of top-quality alloy metal.

|

|

Flat Die: The flat die has many holes for compressing raw materials into pellets. The holes’ diameters of our flat dies range from 6mm to 8mm. Besides, the diameters can also be customized according to our clients’ specific requirements.

|

|

Our ZLSP-D type flat die pellet mill can make pellets from a wide range of raw materials like agro-forestry and other biomass materials. The most common raw materials are sawdust, wood shavings, wood chips, rice husks, straw, peanut shells, etc. Besides, you can make pellets at home or on your farm with our flat die pellet press easily, as they can be moved conveniently.