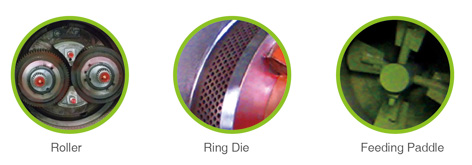

Ring die pellet mills are widely used for large production of wood pellets in industries. They are mainly for commercial use because of their large capacity, structural complexity and higher cost. As its name suggests, the ring die has a wide cylindrical shape and it is mounted vertically. The biomass materials enter the surge bin through a speed conditioner. A screw auger moves the materials into the center of the pellet mill.

Advantages of Ring Die Pellet Mill

There is less wear and tear with the ring die since both the inner and outer edges of the roller traverse the same distance. The rollers in pelletizing process bring extra frication, which accelerates the production of finished pellets due to the additional heat.

Details of Ring Die Pellet Mill

Technical Parameters of Ring Die Pellet Mill

| Type | Capacity | Power | Ring Die Capacity | Pellet Specifications |

|---|---|---|---|---|

| KMPM42 | 1-1.5t/h | 95kw | 800-1000t | 6mm/8mm/10mm/12mm/14mm |

| KMPM508 | 1.5-2t/h | 115kw | 1000-1200t | 6mm/8mm/10mm/12mm/14mm |

| Type | Forming rate | Ability to operate | Noise | Dimensions |

|---|---|---|---|---|

| KMPM42 | ≧95% | ≧20h | ≦88dB[A] | 3300*1200*3943(mm) |

| KMPM508 | ≧95% | ≧20h | ≦90dB[A] | 3450*1470*4445(mm) |

| Type | Weight | Pellet energy consumption | Main motor speed |

|---|---|---|---|

| KMPM42 | ≈3t | ≈85° | 1000r/min |

| KMPM508 | ≈4.5t | ≈80° | 1000r/min |