As for the flat die pellet mills we supply, there are two different kinds. The first kind consists of a series of rotating rollers and a stationary die, namely rotating roller pellet mill. While the second kind of flat die pellet mill is composed of stationary rollers and a rotating die. The flat die of the rotating roller pellet mill has a longer service life (about 2000hours) than the second kind. Besides, rotating roller pellet mill can produce longer wood pellets, including those are more than 3 cm in length.

|

|

| Rotating Roller Pellet Mill | Spare Parts of Pellet Mill |

Video of Installation and Operation of Rotating Roller Pellet Mill

Application

Our rotating roller pellet mill is specially designed to make pellets form a variety of biomass materials, like: sawdust, wood shavings, wood chips, rice husks, straw, chaff, peanut shells, bagassa and alfalfa, etc.

Technical Parameters

| Model | Capacity | Motor Power | Packed Dimensions | Final Pellet Diameter | Material of Flat Die & Roller | Life of Flat Die & Roller |

|---|---|---|---|---|---|---|

| ZLSP300 R-Type | 250-350 kg/h | 22 kw | 1300*600*1400 mm

Weight: 575 kg |

6-12 mm | alloyed steel | min 800 hours |

| ZLSP400 R-Type | 350-450 kg/h | 30 kw | 1400*700*1600 mm

Weight: 810kg |

6-12 mm | alloyed steel | min 800 hours |

QA: the usable life of the motor and gear box is 1 year; that of the upper body and box of the main shaft is five

QA, others: 1 year except aforementioned parts

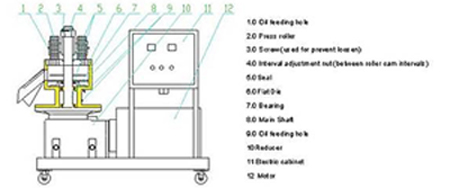

Structure

Special Advantages

- Gears are made of high-quality case-hardened nitrogen-alloyed steel to ensure durability and efficiency.

- Main shaft is specially designed to endure heavy loads and bear strong axial forces.

- Rollers with large diameters increase pelletization rate, pellet uniformity and strength.

- Rollers and dies are equipped with a wear-resistant surface.

- All bearings are sealed to prevent dust from accumulating.

- Pellet diameters vary from 6mm to 12mm.