The processing of soybean oil usually begins with the well preparation of soybeans: the soybeans need to be thoroughly cleaned, dried and dehulled before extracting. De-hulling is done by cracking soybeans and mechanical separation of hulls and cracked soybeans. Magnets are also used to separate iron form soybeans. Soybeans usually need to be heated to around 75°C to coagulate the soy proteins to make the extraction process much easier.

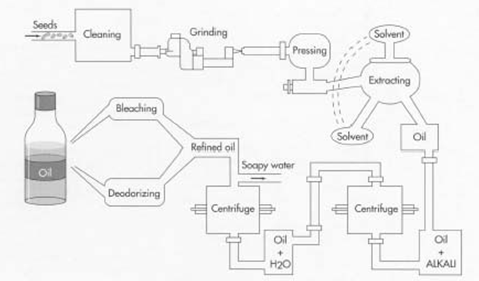

During the processing process of soybean oil, the soybeans are usually cut into flakes and then put in a percolation extractor immerged with solvent. After removing the hexane, the extracted flakes only contain about 1% soybean oil and are used as livestock meal or food products such as soy protein. The hexane is separated from the soybean oil in evaporators. The evaporated hexane is recovered and returned to the extraction process. The hexane free crude soybean oil is then further refined.

Soybean oil refining is another important process. Soybean oil obtained from pressing or solvent extraction process always contains impurities such as phospholipids, FFA, pigment, and other off-flavor impurities. In order to make the oil pure and edible, oil refining process is adopted. The oil-insoluble material are removed with filtration and the soluble materials is removed with different processes including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter and gums) and bleaching (with activated earth or activated carbon to remove coloured impurities, etc).

Soybean Oil Processing Plant

To obtain high-quality soybean oil, a series of soybean oil processing equipment is involved. The soybean oil plant typically contains five steps: oilseed handling/elevator operations, preparation of soybeans for solvent extraction, solvent extraction and oil desolventizing, flake desolventizing, and oil refining. Following pictures are from soybean oil processing plants.

Soybean oil is edible oil with light and clean flavor. It contains 60% polyunsaturated fat and 24% monounsaturated fat, according to the National Soybean Research Laboratory, making it heart-healthy oil.

Soybean oil is extracted mainly by three methods. Solvent extraction is usually with hexane, and the oil yield is typically around 19% (the dreg oil in meal is about 1%). With mechanical pressing, the oil yield is usually around 13% (the dreg oil in cake is around 7%). Another is cold pressing. The soybeans use a small hand operated seed oil press to extract the virgin soybean oil at home.

As a professional supplier, our soybean oil processing equipment adopts the latest advanced technology. They are all of high quality and competitive price! And we also provide our customers with timely delivery, free technical guidance and excellent after sales service!