As a leading Chinese manufacturer and supplier of flour milling equipment, we have been professional for more than a decade. We provide wheat flour milling plants of a wide range of capacities for our customers. Having won CE and ISO9000 certifications, and good reputations worldwide, our customers are pretty satisfied with our wheat flour milling plants.

80-500TPD Wheat Flour Milling Plants

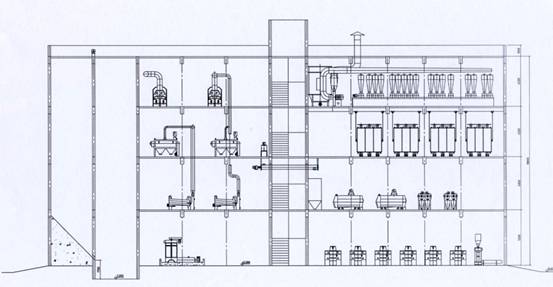

We provide a series of 80-500 ton per day wheat flour milling plants, which is multi-story designed. It uses a square plansifter and newly developed wheat flour milling machines. It enjoys many advantages, like: low investment, compact structure, simple operation, high output rate, low power consumption and long service life. Consequently, it is the first choice of medium and large wheat flour milling plants.

We provide a series of 80-500 ton per day wheat flour milling plants, which is multi-story designed. It uses a square plansifter and newly developed wheat flour milling machines. It enjoys many advantages, like: low investment, compact structure, simple operation, high output rate, low power consumption and long service life. Consequently, it is the first choice of medium and large wheat flour milling plants.

Flour Milling Machines in Multi-story Plant

200TPD Wheat Flour Milling Plant

Technical Specifications of Flour Milling Process:

4B, 7M, 1S, 2T, 2BrF, 1BrB and 5P.

Wheat Flour Process Machine:

3 sieves, 2 scourers, 2 stoners, 1 foreign seed extractor, 3 magnetic separation units, and 1 dampener.

| Grades | Capacity (t/d) | Power consumption per ton of flour (KWh) | Power (KW) | Workshop Dimensions (L*W*H)(m) |

|---|---|---|---|---|

| Grade2, Special flour | 200 | 60-70 | 600 | 45*7.5*23 |

The wheat flour milling processes in our plants can be stacked over two or more storeys.

| Model | Workshop size | Wheat Flour Milling Process | Power (KW) |

|---|---|---|---|

| 250 TPD Wheat Flour Milling | 48×7.5×27.6Six-stories twin-span construction |

Cleaning:100×200 sieve, 100×150 roto-sifter, 45×100 wheat scourer, 40 wheat brushers, 100 cyclone sieves, 125 gravity stoners, 150 sucking stoners, foreign seed extractor, 15 intensive dampeners, auto-atomizing dampener, and a duster and elevator combined cleaning process. Flour milling:16 sets of 100×2 electronically controlled flour mills, 5 sets of 8×22 high plane sieves, 1 set of 4×24 plane sieves, 5 sets of 49×2×3 purifiers, 3 sets of 45×2 multiple bran finishers, vibrating circular screen, bran brush, pulsed jet filter, and an auto bran packing machine that combines the 5B, 2S, 12M, and 10P flour milling processes. |

780 |

| 300 TPD Wheat Flour Milling | 50×7.5×27.6Six-stories twin-span construction |

Cleaning:150×200 sieve, 125×150 plane rotation sieve, 45×100 wheat scourer, 45×100 wheat scourer, 40 wheat brushes, 100 cyclone sieves, 125 gravity stoners, 150 sucking stoners, foreign seed extractor, 15 intensive dampeners, auto-atomizing dampener, and a duster and elevator combined cleaning process. Flour milling:16 sets of 125×2 electronically controlled flour mills, 5 sets of 8×22 high plane sieves, 1 set of 4×24 plane sieves, 6 sets of 49×2×3 purifiers, 3 sets of 45×2 multiple bran finishers, vibrating circular screen, bran brush, pulsed jet filter, and auto bran packing machine that combine the 5P, 2S, 12M, 12P and flour milling processes. |

1070 |