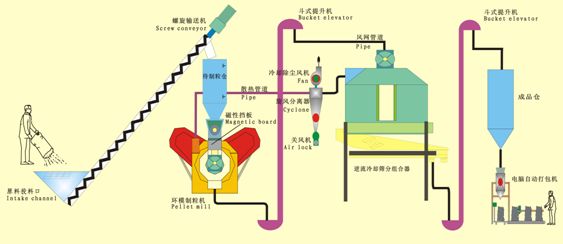

A wide variety of wood pellet milling plants are provided by us. Our C55 wood pellet line can produce wood pellets form 500kg to 700kg per hour. In fact, it is the complete wood pellet plant from crushing, which includes screw conveyor, crusher, silo, ring die pellet mill, cooler, grading sieve machine and control cabinet, etc.

The ring die wood pellet mill is mainly composed of the feeder, conditioner, granulating machine, conveyor and lubricating part. The most proper moisture content of the raw materials is less than 15%, under which the pellet mil can have a long-time excellent performance. The raw material powders enter conditioner, and then they are stirred through stirring rod equably.

If necessary, oil or molasses, or these two things together, can be added into the powders of the raw material. Then, they are quenched and tempered, and the temperature of the mixed powders will be from 64° C to 85° C, and relative humidity from 14% to 16%. After iron impurities are removed, the mixed powders will be sent to the ring die pellet mill for pelletizing.

Features: Low investment, low power consumption, low noise, easy operation and long service life.

Key Technical Parameter of Wood Pellet Line

Capacity: 500-700kg/h

Moisture content of raw materials: 12%–15%

Pellet’s diameter: 6mm

Pellet’s density: 1.2g/cm3—1.3g/cm3

Pellets rate: ≥ 95%